FAST, RELIABLE, SAFE

LINER EXCHANGE MACHINES

The preferred choice for mill operators globally. Our expanded range – 400 kg to 9T capacities – ensures fast, reliable, safe mill relining is now available to every site.

RUSSELL Liner Exchange Machine Range

Fast, reliable, safe, RUSSELL Liner Exchange Machines are the perfect match for reaching your mill relining potential. They embody everything RME has learnt over 35+ years and 550+ machines manufactured to deliver superior productivity, serviceability, lifecycle cost and safety.

And now, RME’s modular systems engineering approach offers the industry's widest range of models – from field-upgradeable automated systems to compact liner handlers – for mills large, medium and small. So you are certain to find an affordable, future-proofed solution to match your mine site needs.

It’s never been easier to enter the world of advanced relining and achieve visible, defensible and sustainable improvements in concentrator performance and mill relining safety.

Available in 400 kg to 9T lifting capacities.

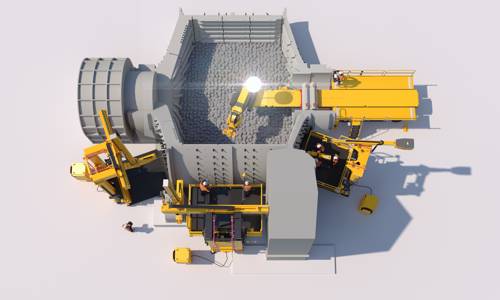

RUSSELL 7-R AUTOMOTION MRM

The world's first semi-automated mill relining machine for relining from outside of the mill.

Available in 4500 kg – 9000 kg capacities.

RUSSELL 7-S+ MRM

RME's signature 7-axis machine now future-proofed with AutoMotion-ready hardware.

Available in 4500 kg – 9000 kg capacities.

RUSSELL 7-S MRM

Signature performance and the industry’s most widely adopted mill relining machine.

Available in 2500 kg – 9000 kg capacities.

RUSSELL TWIN 7 MRM

Reline both sides of the mill simultaneously and increase your relining speed – safely.

Available in 2500 kg – 9000 kg capacities.

RUSSELL 3/7-E 1500 Hybrid MLH/MRM

Can be either – a 3-axis handler that evolves to a 7-axis MRM – to advance relining speed and safety.

1500 kg capacity

RUSSELL 3-L 1000 MLH

Giving smaller mills the certainty of RME quality and reliability, with the means to improve safety and mill availability.

1000 kg capacity.

MILLMAST POWERSHIFT

Shift your relines into high gear with the compact in-mill erected liner handler for space constrained mills.

400 kg capacity.

RUSSELL 3V Mill Liner Handler

The RUSSELL 3V Mill Liner Handler is for lifting and manoeuvring liners in vertical axis stirred grinding mills.

Up to 13T capacities.

RUSSELL 6V Mill Relining Machine

RUSSELL 6V MRMs are built for heavy-weight auger liner exchange in large vertical axis stirred grinding mills.

Up to 10T capacities.