MILLMAST POWERSHIFT

Let MILLMAST Powershift handle the heavy lifting. This compact in-mill erected liner handler, designed for space-constrained mills, streamlines relining, and most importantly, it prioritises safety.

300 kg capacity.

MILLMAST Powershift is a compact mill liner handler tailor-made for smaller space-constrained mills, especially those still wrestling with manual relining. Simple set up and operation, robustly-built to handle liners up to 300kg, MILLMAST Powershift prioritises crew safety by reducing manual liner lifting risks and accelerating relining speed. Tough and fatiguing relines in tight spots can be a thing of the past. Let MILLMAST Powershift handle the heavy lifting.

Benefits

- Safety improvement: Reduces fatigue, manual handling risks, and crew inside the mill.

- Reduced mill downtime: Optimise liner design for faster relining and higher mill availability.

- Space-saving design: Compact footprint, store, transport and manoeuvre easily.

- Cost-effective: Low upfront and maintenance costs.

- Versatile: Works across multiple mill dimensions.

ADDITIONAL INFORMATION

-

- Erected in minutes and able to handle liners weighing up to 300kg

- MILLMAST Powershift eliminates all manual liner lifting for safer operation

- Power is sourced from the MILLMAST Powerpack outside the mill

- Sophisticated design minimises component weight for fast and safe set up

- Trained operators can set up the MILLMAST Powershift in under five minutes

- Custom manufactured to work across a range of mill dimensions

- -20°/+30° boom articulation allows crews to reline multiple rows above charge height before inching the mill

-

- MILLMAST Powershift is a fit-for-purpose safety and productivity relining solution for smaller and space-constrained mills.

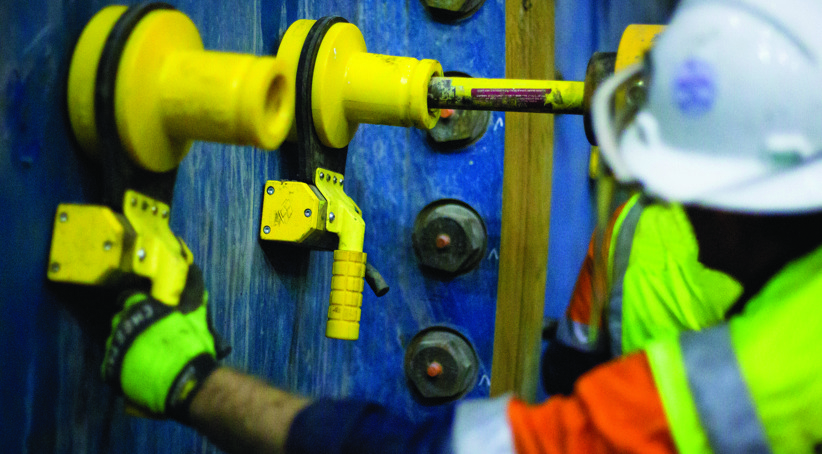

- MILLMAST Powershift can be used in combination with RME’s Liner Bolt Removal Tools (LRTs) for optimised relining safety and productivity.

- THUNDERBOLT Recoilless Hammers are available in different models for relining all grinding mill sizes and liner types.

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs sold and manufactured.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME assets & services.

"MILLMAST Powershift is a fit-for-purpose safety and productivity relining solution for smaller and space-constrained mills. Its patented design reduces manual lifting hazards, enabling mills to be relined safer and faster, with reduced mill downtime."

WATCH A VIDEO DEMONSTRATION

Shift your mill relines into high gear with MILLMAST POWERSHIFT – the industry’s most compact mill liner handler (MLH) for smaller space constrained mills with high ball charge levels. Erected in minutes and able to handle liners weighing up to 300kg, MILLMAST Powershift eliminates manual liner lifting to improve safety and productivity. Let MILLMAST Powershift handle the heavy lifting.

Related products

THUNDERBOLT 250

Lighter in weight but not in impact, the portable, pneumatic THUNDERBOLT 250 Recoilless Hammer helps small mills and field service crews to increase productivity and safety.

Read More

THUNDERBOL T-MAG MOIL ACCESS GUIDES

T-MAGs are designed for use with THUNDERBOLT Recoilless Hammers to make liner bolt knock-in safer and more efficient, and protect the mill shell.

Read More

THUNDERBOLT MOBILE Elbow Jib

The pneumatic-powered THUNDERBOLT Mobile Elbow Jib is a perfect partner for the THUNDERBOLT 500 Recoilless Hammer. It’s safe, versatile, and will raise your productivity.

Read More

O-ZONE LINER LIFTING TOOLS

When it’s time to safely, quickly secure and pick up worn liners from the mill charge, RME’s range of O-ZONE Liner Lifting Tools provide a safe alternative for liner transport.

Read MoreOur Experts