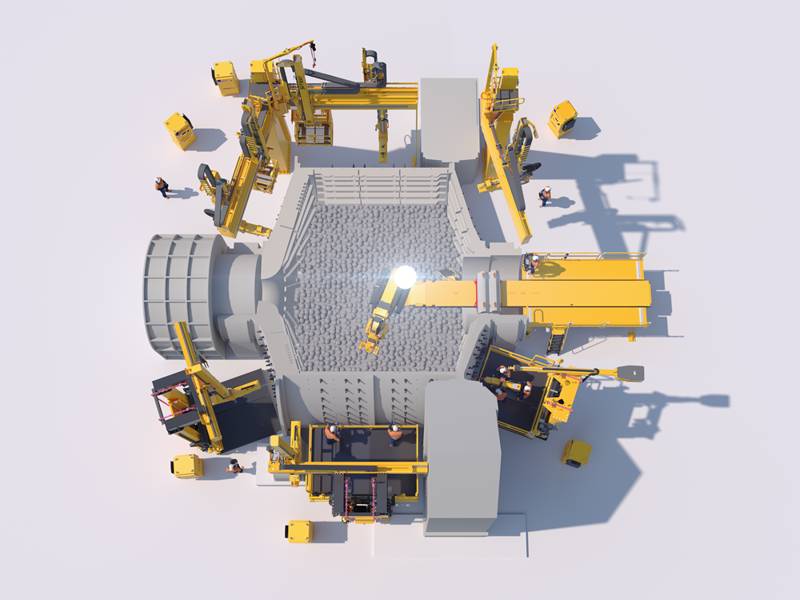

RUSSELL 7-R AUTOMOTION™ MRM

The world's first semi-automated mill relining machine for relining from outside of the mill.

Available in 4500 kg – 10 tonne capacities.

THE FUTURE IS NOW

Our relentless pursuit to improve safety and productivity has driven us to engineer a future where relining is performed safely from outside the mill – at faster speeds than ever before.

For almost 40 years, RME has led the world in the engineering of fast, reliable, safe technologies and methodologies for every step on the mill relining path. Today, this integrated ecosystem has evolved to incorporate semi-autonomous mill relining capabilities.

The 'RME Advanced Technology Mill Relining System' can now remove worn liners, and place new ones with millimetre precision — all from the mill's exterior and with no one inside.

Furthermore, RME's modular engineering allows customers to adopt automation progressively, minimising technical and operational risks.

With RME by your side, you can future-proof your operations while simultaneously moving operators out of harm's way and taking relining off the shutdown critical path.

Click on the tiles below to learn more about the transformative products that are part of the RME Advanced Technology suite.

The world's first semi-automated mill relining machine for relining from outside of the mill.

Available in 4500 kg – 10 tonne capacities.

Introducing the RUSSELL Claw™ – the new master of muck-out. It eliminates hazardous manual liner slinging, enabling worn liner removal with no crew on the charge. Lifting capacity up to 8000 kg.

RME BOLTBOSS is an innovative universal toolset that enables safer securing of liners, nuts and bolts from the mill’s exterior without the need for crew to be inside.

“Our goal is to provide the means for operators to reline mills with no-one inside, an environment which radically improves safety and relining speeds – consistently, repeatably and sustainably – for greater concentrator performance.”

Give your crews greater, and ergonomically-safer, reach outside the mill. Plus they're field-upgradable to THUNDERBOLT SKYPORT.

Portable and modular, THUNDERBOLT SKYPORT is the lift-in version of the fixed plant THUNDERBOLT SKYWAY, RME's semi-automated knock-in technology.

THUNDERBOLT SKYWAY roboticises the operation of THUNDERBOLT Hammers to vastly improve knock-in speed and safety – consistently, repeatably, sustainably.

"RME's approach to mill relining automation prioritises safety at every step. First, we take mature and proven technologies and future-proof them with automated capabilities. Second, we take a systems approach to ensure no new risks are introduced inside and outside the mill. Third, we’ve developed a carefully staged and fully supported implementation program which minimises technical and cultural change risks. Our approach is fast, reliable and ensures the safety of your reline crew."

RME's Founder and Chief Engineer, Dr John Russell, speaks about the company’s pioneering efforts to enable relining from outside the mill and its impact on the future of mineral processing.

Read More

MILL RELINE DIRECTOR (MRD) discrete event capture, analysis and 'digital twin' simulation provides clear line of sight into the complex process of mill relining.

Read More

A MILL RELINE DIRECTOR Safety film study benchmarks your safety performance and provides practical risk reduction strategies for your next reline event.

Read More

We can help you reduce shutdown duration, achieve maintenance predictability, eliminate risk and increase mill availability.

Read More