RUSSELL 7-R AUTOMOTION™ MRM

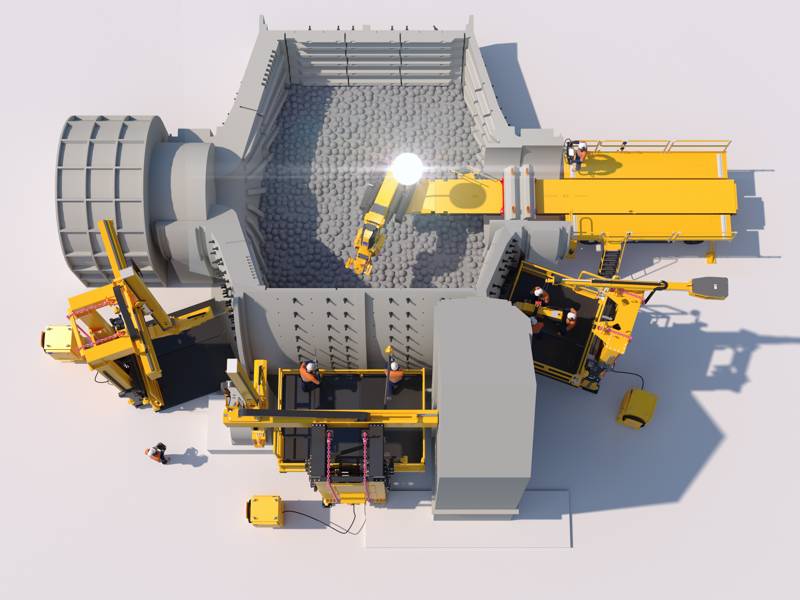

The world's first semi-automated mill relining machine for relining from outside of the mill.

Available in 4500 kg – 10 tonne capacities.

MAXIMUM ASSET LIFE FOR LOWER TOTAL COST

Trusted globally for every 40 ft SAG, we're now bringing RME safety, innovation, performance, reliability and long-life standards to even the smallest capacity machines.

"We've re-imagined the RUSSELL Liner Exchange Machine range. Not only is it underpinned by RME’s trusted established technology, our modular systems engineering offers more models for our industry and automation optionality for our RUSSELL 7 range*. This means there's an affordable and future-proofed RUSSELL Mill Relining System for all mills, both large and small. Now every site can achieve a step-change in safety and mill availability."

The world's first semi-automated mill relining machine for relining from outside of the mill.

Available in 4500 kg – 10 tonne capacities.

RME's signature 7-axis machine now future-proofed with RME AutoMotion™-ready hardware.

Available in 4500 kg – 10 tonne capacities.

Signature performance and the industry’s most widely adopted mill relining machine.

Available in 2500 kg – 10 tonne capacities.

Can be either – a 3-axis handler that evolves to a 7-axis MRM – to advance relining speed and safety.

1500 kg capacity

Giving smaller mills the certainty of RME quality and reliability, with the means to improve safety and mill availability.

1000 kg capacity.

Let MILLMAST Powershift handle the heavy lifting. This compact in-mill erected liner handler, designed for space-constrained mills, streamlines relining, and most importantly, it prioritises safety.

300 kg capacity.

The RUSSELL Claw grapple attachment for your RUSSELL Mill Relining Machine means business when it comes to the muck out phase of mill relining.

Strong and durable, its powerful jaws and 360 degree rotation will grab knocked-in worn liners from wherever they fall and deliver them straight to the liner cart for exiting.

But above all, safety is its first priority. The RUSSELL Claw eliminates crew on the charge and the need for for manual liner slinging during worn liner removal.

Suitable for most RUSSELL 7 and 8* Mill Relining Machines 2500kg– 8000kg

*Retrofits required for RUSSELL 7 and 8-axis MRMs pre-2023

570+ RUSSELL Liner Exchange Machines and 1300+ THUNDERBOLT Recoilless Hammers delivered.

90%+ of RUSSELL Liner Exchange Machines ever manufactured remain in service. Our machines are safe and built to last.

We're are the mill relining equipment and process specialists. This is what we know and do. Trusted by 440+ mine sites globally.

We combine 40+ years of OEM experience with data-driven insights and industry benchmarking by MILL RELINE DIRECTOR.

Mineral processors need to address issues that are more challenging and more urgent than ever.

On one hand they must reduce the risks that remain associated with hazardous mill relining. On the other, maximise mill availability for meeting the world’s mineral needs.

It is this pursuit to improve safety and productivity that drives RME to innovate for our industry.

This has led us to envision a future where relining is performed with no one inside the mill, an environment that allows us to accelerate the machines and reline at faster speeds than ever before.

And now this future is here.

"The RME Customer Support Technician's engagement and 'zero harm' attitude, as well as high regard for our site's processes, was very refreshing. Certainly the kind of partner we like to engage with."

*Applicable to RUSSELL 7 Model R AutoMotion Mill Relining Machines, RUSSELL 7 Model S+ Mill Relining Machines and RUSSELL 7 Model S Mill Relining Machines manufactured from 2024 onwards. Contact RME to learn more.