THUNDERBOLT RECOILESS HAMMERS

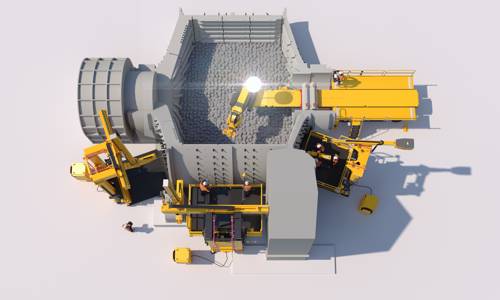

Simply the industry's fastest, toughest and safest method for liner bolt knock-in. And we have the widest range for all your worn liner removal needs.

THUNDERBOLT RECOILLESS HAMMERS

Since their introduction in 1997 and with more than 1100 units sold worldwide, THUNDERBOLT Recoilless Hammers are the safest and most advanced liner removal tools (LRTs) for grinding mill relining.

As the world's only truly recoilless hammer, and preferred by mill operators and reline crew alike, THUNDERBOLTs stand alone for productivity, reliability, longevity ― and mill availability.

THUNDERBOLT MAGNUM 2000

The mighty THUNDERBOLT MAGNUM 2000 is the industry’s most powerful recoilless hammer, delivering the ultimate in impact energy per blow.

Read more

THUNDERBOLT MAGNUM 1000

The THUNDERBOLT MAGNUM 1000 is the industry's most productive hammer yet. It's high-energy rapid-fire rate will shorten knock-in times and improve operator safety.

Read more

THUNDERBOLT 1500 SP

Favoured by mill operators and reline crews for its legendary reliability, the THUNDERBOLT 1500 SP is renowned for delivering powerful productivity and supreme operator safety.

Read more

THUNDERBOLT 750 SP

A field favourite, the THUNDERBOLT 750 Special Performance Recoilless Hammer is highly regarded for its versatility, work-rate, responsive handling and RME reliability.

Read more

THUNDERBOLT 500

The THUNDERBOLT 500 Recoilless Hammer is our top-of-the-line pneumatic liner bolt removal tool. It packs a punch and eliminates hazardous practices which impact safety.

Read more

THUNDERBOLT 250

Lighter in weight but not in impact, the portable, pneumatic THUNDERBOLT 250 Recoilless Hammer helps small mills and field service crews to increase productivity and safety.

Read more“We know from 35-plus years partnering with customers on mill relines, there’s no one-size-fits-all solution to worn liner bolt knock-in. In fact, industry benchmark operations will use the hardest hitting hammers for difficult-to-dislodge bolts at the discharge end and breaking-in on the first inch, then swap to a high repetition hammer for ploughing through the shell liners."