THUNDERBOLT MAGNUM 2000

The mighty THUNDERBOLT MAGNUM 2000 is the industry’s most powerful recoilless hammer, delivering the ultimate in impact energy per blow.

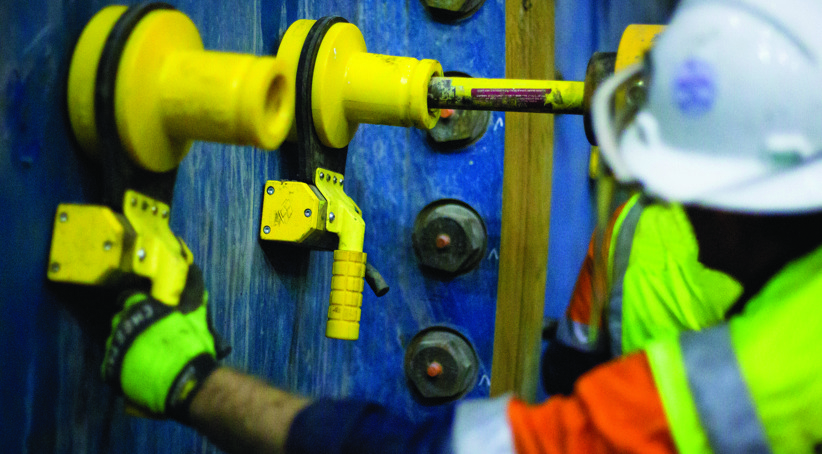

The THUNDERBOLT MAGNUM 2000 is the mill relining industry’s most powerful recoilless hammer, conclusively delivering the ultimate in impact energy per blow. For applications where maximum force and momentum are required, the THUNDERBOLT MAGNUM 2000 will easily expedite the toughest of knock-in phases, in the most challenging of conditions for fast, reliable, safe relines and greater mill availability.

BENEFITS

- Combines sheer power and force with best-in industry equipment reliability and longevity

- Tough, stuck and deeply-wedged liner bolt removal made faster, easier and safer

- Reduced servicing intervals and lifecycle costs

- Improved component accessibility for ease of maintenance

- Optimised asset health with intelligent on-board monitoring

- Unmatched operator safety with advanced new shock reduction and ergonomics

- Reduced knock-in duration means faster relines and opportunities for improving concentrator profitability

ADDITIONAL INFORMATION

-

- New operator-programmable ‘MAGNUM Mode’ for precision safety and more granular control

- Extreme high-energy impact at 2000 joules per blow (33% increase) in MAGNUM Mode and 1500 joules in standard mode*

- Consistent, electronically-controlled strike rate of 70 blows per minute (BPM) in MAGNUM Mode (16% increase) and 80 BPM (33% increase) in standard mode*

- Extended service intervals at 100,000 blows (150% increase)*

- Groundbreaking recoil dry fire shock reduction (90% decrease) minimises machine stress and operator fatigue*

- Removable casing for easier component accessibility and superior repairability

- Electronically-managed dual-action contact trigger safety mechanism eliminates risk of accidental firing

- Redesigned hydraulic systems for improved operational safety and use

- Integrates with the new THUNDERBOLT MAGNUM Power Pack, which is also interchangeable between the THUNDERBOLT MAGNUM 1000 and 2000 models

*Compared to the THUNDERBOLT 1500 Special Performance Recoilless Hammer

-

- Ideally suited to completing the toughest liner bolt removal jobs – whether it’s large mills with heavyweight liners or discharge end stuck bolts – in the shortest possible time-frame

- Combines maximum power with cutting-edge technology for consistently fast, reliable and safe relines

- Early-stage commercial trials have demonstrated worn liner knock-in with reductions in and elimination of lancing, capturing further time savings

- RME stands ready to guide Customers through the THUNDERBOLT selection process for their mill requirements

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs engineered, manufactured and delivered.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME equipment & services.

"With up to an astounding 2000 joules per blow, the new THUNDERBOLT MAGNUM 2000 is unsurpassed when it comes to completing the toughest liner bolt removal in the shortest possible time-frame while keeping your reline crew safe from harm."

Compare THUNDERBOLT Recoilless Hammers

MODELO THUNDERBOLT |

MAGNUM 2000 |

MAGNUM 1000 |

1500 SP |

750 SP |

500 |

250 |

|---|---|---|---|---|---|---|

ENERGÍA |

Hidráulica |

Hidráulica |

Hidráulica |

Hidráulica |

Neumática |

Neumática |

FUERZA GOLPE (J) |

2000 MM 1500 SM |

1000 MM 750 SM |

1500 |

750 |

500 |

250 |

Intervalo servicio |

100.000 golpes o 2 años |

100.000 golpes o 2 años |

40.000 golpes o anualmente |

40.000 golpes o anualmente |

40.000 golpes o anualmente |

Anualmente |

Tasa golpe (GPM) |

80 - Modo Estándar 70 - Modo MAGNUM |

160 - Modo Estándar 140 - Modo MAGNUM |

60 – Modo Estándar |

90 – Modo Estándar |

60 – Modo Estándar |

60 – Modo Estándar |

Related products

THUNDERBOLT MAGNUM 1000

The THUNDERBOLT MAGNUM 1000 is the industry's most productive hammer yet. It's high-energy rapid-fire rate will shorten knock-in times and improve operator safety.

Read More

THUNDERBOL T-MAG MOIL ACCESS GUIDES

T-MAGs are designed for use with THUNDERBOLT Recoilless Hammers to make liner bolt knock-in safer and more efficient, and protect the mill shell.

Read More

THUNDERBOLT MAGNUM Mobile Jib

The THUNDERBOLT MAGNUM Mobile Jib is our highest reaching jib and tailor-made to ensure hammers are suspended safely and perform superbly.

Read More

THUNDERBOLT ELEVATING PLATFORMS

Give your crews greater, and ergonomically-safer, reach outside the mill. Plus they're field-upgradable to THUNDERBOLT SKYPORT.

Read More

THUNDERBOLT SKYPORT

Portable and modular, THUNDERBOLT SKYPORT is the lift-in version of the fixed plant THUNDERBOLT SKYWAY, RME's semi-automated knock-in technology.

Read More

THUNDERBOLT ORBIT

The THUNDERBOLT ORBIT™ is a literal revolution for cone crusher head nut change outs and the fastest, safest method for removal and tensioning by far.

Read MoreOur Experts

Evgeny Klyukin

Business Development Manager, Central Asia/Middle East/Europe/South Asia

Kabelo Mogobye

Regional General Manager, Africa & South Africa, Leadership Team

Owen Flemming

Regional General Manager, North/Central America, Leadership Team

Denny Wisely

Vice President Sales & Business Development, North America