RUSSELL LINER EXCHANGE MACHINES

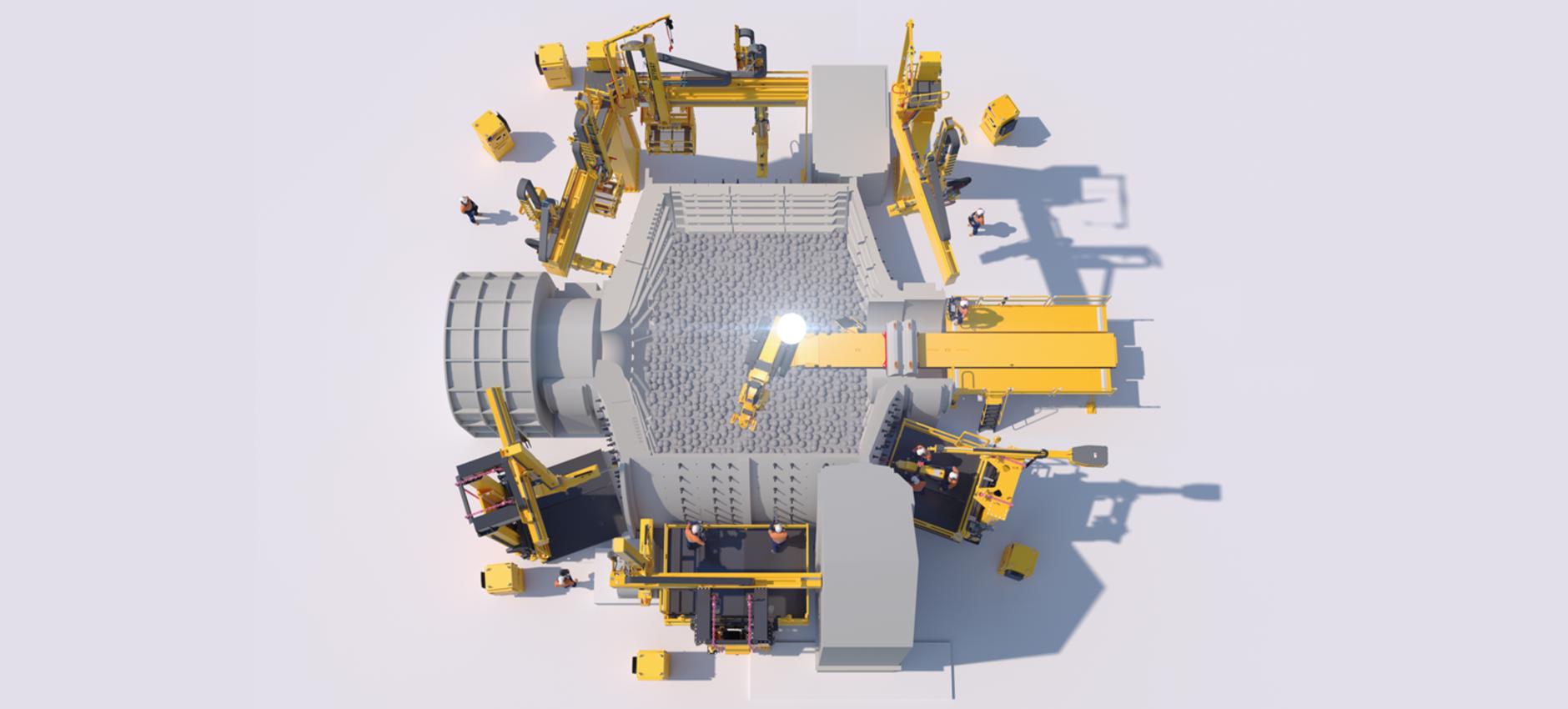

The trusted choice for mill operators globally. Our expanded, higher-performing range – from <400 kg to 10 tonne capacities – ensures fast, reliable, safe mill relining is available to every mine site.

FAST, RELIABLE, SAFE

A testament to four decades of Customer and industry partnership, purposeful innovation, shorter mineral concentrator shutdowns, and safer conditions for reline crews — RME marks the manufacture of its 600th RUSSELL Mill Relining Machine. Discover the story behind this milestone and where this machine is headed.

Trust RME to raise the standard

RME’s expanded, future-proofed, field-upgradable RUSSELL Liner Exchange Machine range ensures fast, reliable, safe relining is even more accessible to every mine site. Our industry-leading technologies include roboticised, mechanised and mill liner handler solutions from <400kg up to 13 tonne capacities. Trusted and relied upon by mill operators and reline crews at 440 mine sites globally.

Trust RME to raise the standard

The RME Advanced Technology Mill Relining System™ is here. This groundbreaking product suite removes reline crews from hazardous zones inside and around the mill during liner exchange. Experience faster relining speeds with roboticised technology, and greater mill availability. Proven and commercially deployed—the future is now.

Trust RME to raise the standard

Explore the masterful RUSSELL Claw and RME BOLTBOSS™, part of the RME INSIDEOUT® Technology family, eliminating personnel from hazardous zones inside the mill during liner exchange. Compatible with all liner types and designed for RUSSELL Mill Relining Machines.

Trust RME to raise the standard

Reach higher, work safer, knock-in faster with THUNDERBOLT® – the industry's reliable, trusted and comprehensive worn liner removal system. THUNDERBOLT® Recoilless Hammers from 250 to 2000 Joules ⋅ Jibs and monorail suspension ⋅ THUNDERBOLT Elevating Platforms™ ⋅ THUNDERBOLT SKYPORT™ ⋅ THUNDERBOLT SKYWAY®

RME is the world's trusted Original Equipment Manufacturer (OEM) of fast, reliable, safe grinding mill relining technologies, asset support and optimisation services.

Mill relining is the most specialised and critical task in concentrator maintenance—directly impacting shutdown duration and mill availability, and therefore influencing throughput and profitability.

RME’s driving passion has always been to eliminate fatal risk and visibly, defensibly, and sustainably improve our Customers’ concentrator performance.

Since 1985, the RME Mill Relining System—a suite of products for every step in the relining path—has significantly reduced relining times and created safer working environments for our Customers.

Today, RME remains committed to helping every Customer—past, present, and future—maximise the performance potential of their RME Mill Relining System.

Discover how the RME Mill Relining System is delivering exceptional safety and performance for Customers around the world.

The trusted choice for mill operators globally. Our expanded, higher-performing range – from <400 kg to 10 tonne capacities – ensures fast, reliable, safe mill relining is available to every mine site.

Since 1997, THUNDERBOLTs have revolutionised liner bolt removal time and safety. See the wider range and their new faster, safer semi-automated capabilities.

Ensure mill relining equipment safety, productivity and longevity with RME's regionally-based inspections and servicing, critical spares provisioning and certified training.

Since the introduction of the RME Mill Relining System, our Customers have significantly reduced mill relining times. In addition, many of the safety risks associated with manual relining activities have been eliminated—helping create safer, more predictable shutdowns and improving mill availability.

This same pursuit has driven the development of RME's Advanced Technology suite, which removes the need for crew to be inside the mill during relining. This enables significantly faster machine movements and relining speeds—without compromising safety.

For over 40 years, we’ve partnered with hundreds of mine sites globally to optimise mineral processing operations. Our mission is to work with you to deliver shorter shutdowns, higher mill availability, and safer working environments.

RUSSELL MRMs manufactured since 1985

RUSSELL MRMs still in service and supported RME

THUNDERBOLT Recoilless Hammers manufactured since 1990

Mine sites / Countries with RME assets

International Sales and Service Centres

Employees worldwide