RUSSELL MILL SURVEILLANCE

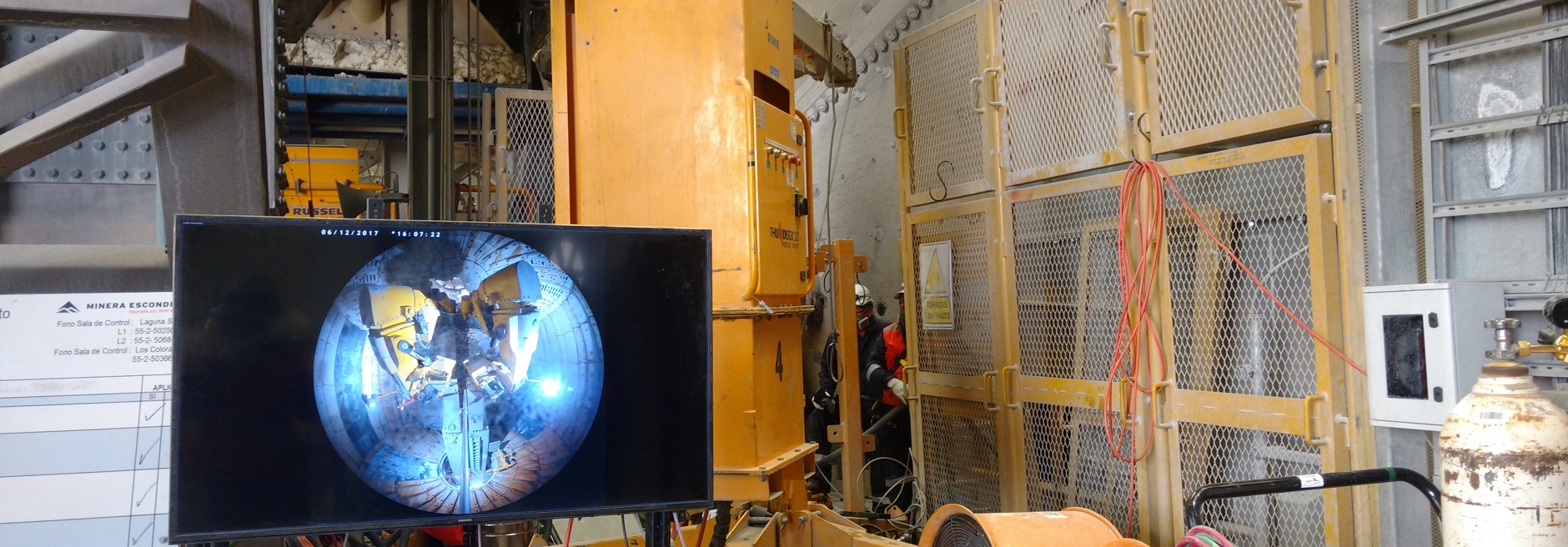

RUSSELL Mill Surveillance is a real-time camera feed that helps mill operators monitor the progress and safety of their mill relining operations.

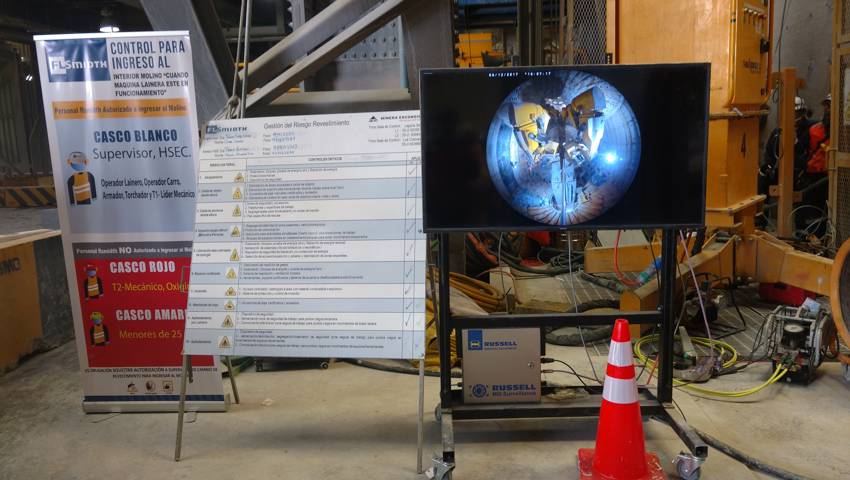

RUSSELL Mill Surveillance is a technology innovation that can identify risky reline behaviours and maximise personnel safety. With high quality cameras raised above the RUSSELL Mill Relining Machine (MRM) providing 360-degree colour vision in the mill, RUSSELL Mill Surveillance is an effective way to check on the progress of a reline, conduct safety audits and help reduce hazards to relining personnel.

BENEFITS

- Superior system for auditing safe work practices during relines.

- Identify and rectify unsafe work behaviours enabling best practice training for personnel.

- High-quality safety solution tailored to the mining environment.

- Engineered for continuous footage with review and export capabilities.

- Camera footage helps with decision-making and budget planning.

- Real-time safety feed means opportunities for improving mill availability.

- In-mill surveillance cameras remove the need for concentrator management and safety personnel to enter the confined space of the mill.

ADDITIONAL INFORMATION

-

- 24/7 ability to monitor reline activities and progress

- High-quality, colour footage makes in-mill visibility efficient and effective

- Multi day continuous high resolution recording, allowing diagnostic review of reline footage in the event of an incident

- Wide-angle cameras can be mounted on the RUSSELL MRM turntable

- 360 degree high-definition camera option is positioned above the RUSSELL MRM operator

- Engineering assessment of interface considerations and local power supplies specific to each site provided

-

- Ideally suited for safety personnel and management wishing to observe reline progress without entering the confined space of the mill

- Reduces the visual barrier for managers wishing to enforce safe work practices that are consistent with site standards

- Demonstrates a proactive, safety solution system to identify and mitigate hazardous processes

- Allows for development training of personnel to achieve best practice relining

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs engineered, manufactured and delivered.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME assets & services.

"Use RUSSELL Mill Surveillance to see reline activities and progress, all without having to enter the mill yourself."

Related products

RME EYE

The RME EYE Visibility Camera System improves the MRM operator’s view of critical work areas and reduces the risk of person and operating mobile plant interactions.

Read More

RUSSELL MILLBRITE IN-MILL LIGHTING

RUSSELL MILLBRITE In-Mill Lighting will improve reline safety and productivity with its simple operation and near-daylight visibility.

Read More

RUSSELL LED WORK LIGHTS

RUSSELL LED Work Lights deliver focused, high-intensity illumination to boost in-mill visibility.

Read More

RUSSELL RADIO REMOTE JOYSTICK CONTROL

Safe and accurate remote control of your RUSSELL Liner Exchange Machine's every function from anywhere around the mill.

Read MoreSS&O Sales Team

Owen Flemming

Regional General Manager, North/Central America, Leadership Team

Denny Wisely

Vice President Sales & Business Development, North America

Lyle Hobbs

Service Account Manager, North America

Manuel Galvez

Regional General Manager, South America, Leadership Team