MILL RELINE DIRECTOR SAFETY

A MILL RELINE DIRECTOR Safety film study benchmarks your safety performance and provides practical risk reduction strategies for your next reline event.

MILL RELINE DIRECTOR Safety is a proven, powerful discrete event capture and analysis methodology that benchmarks real-world safety performance and provides verifiable risk improvement strategies for your next reline.

MRDS assesses and benchmarks your current relining safety and provides risk reduction and elimination recommendations. Through MRD’s discrete event simulation and deep learning analysis, we help our Customers discover relining improvement pathways and this is especially relevant at a time when finite site resources may need recalibration in response to market forces.

BENEFITS

- Know your real-world mill relining risks with certainty.

- Benchmark against safety industry standards.

- Calibrate risk reduction available through equipment upgrades and improved processes and behaviours.

- Understand pathways for safety optimisation.

- Have assurance that risks are being managed effectively.

- Make better, data-driven decisions which improve relining and operational safety.

ADDITIONAL INFORMATION

-

- Integrated program – software, camera hardware, safety industry standards, RME reline expertise

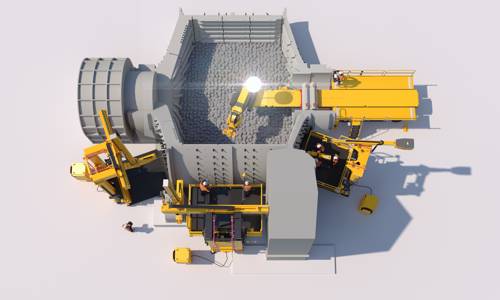

- Reline video capture – utilising up to 12 cameras placed in and around the mill

- Reference reline study – specific to your site, so all mill relining-related activities can be assessed in terms of safety and risk

- Reline safety report – includes qualitative data identifying at-risk conscious and unconscious behaviours, processes or incidents, and quantitative data with incident rates based on issue severity

- Reline safety optimisation – defensible, verifiable recommendations for risk elimination such as mill circuit design, reline process optimisation, equipment upgrades, and crew practices

-

- Capture internal and external mill conditions during a reline

- Identify and assess mill relining risks

- Model and plan reline safety improvements

- Audit subsequent relines to ensure safety and risk compliance

- Determine crew training requirements

- Bolster organisational and operational safety, risk and compliance programs

- Guide CAPEX decision-making on reline equipment upgrades and advanced automation technologies

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs engineered, manufactured and delivered.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME equipment & services.

"MILL RELINE DIRECTOR Safety greatly informed our decision-making as we progressed toward safer mill relining. The program delivered key insights that led us to optimise processes and introduce advanced, automated technologies which reduced risk exposure for our people."

Related products

RUSSELL RESCUE RAISE

The RUSSELL RESCUE RAISE is a mobile jib and stretcher system that gives crews a safe, reliable way of responding to a medical emergency inside the mill.

Read more

RUSSELL HEIGHT SAFETY

RUSSELL Height Safety products protect your crews by providing safe travel and fall protection solutions for your RUSSELL Mill Relining Machine.

Read moreSS&O Sales Team

Matthew B. Thompson

Service Account Manager - APAC

Gary Medill

Service Account Manager - APAC

Denny Wisely

Vice President Sales & Business Development - North America

Samuel Mossaad

Service Account Manager - Canada

Lyle Hobbs

Service Account Manager - North America