TRANSPORTERS

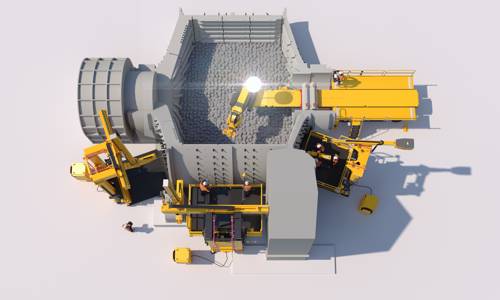

Built to work over the long haul, RUSSELL Feed Chute Transporters (FCTs) and RUSSELL High-Pressure Grinding Rolls (HPGRs) can be relied on to take the load off.

Transporters

RUSSELL Feed Chute Transporters (FCTs) and RUSSELL High Pressure Grinding Rolls (HPGRs) ensure reliable and efficient onsite transport, which is vital for plant inspections, maintenance and safety.

Rapid extraction, transportation and replacement of feed chutes is vital for mill inspections, maintenance and fast relining. It is the first major activity once the mill is shut down and allows access inside the mill. As a result of constant vibration and harsh conditions inherent in plant settings, as the feed chute ages, the harder it can be to remove. This is exacerbated with the trend towards bigger chutes.

Built to work over the long haul, RUSSELL FCTs can be relied upon to take the load off – whether it’s removing a fully-choked feed chute or protecting plant floor structural integrity. They are robust, reliable and safe, and deliver outstanding maneuverability.

RME has a wide range of RUSSELL FCTs for every plant situation:

—RUSSELL Multi-Wheel Feed Chute Transporter

—RUSSELL Classic Feed Chute Transporter

—RUSSELL Rail Feed Chute Transporter

—RUSSELL Unpowered Rail Feed Chute Bases

—Four (4), six (6), eight (8) and ten (10) rubber tyre options

—40T to 100T payload capacities

—Two (2WD), four (4WD), and multi-wheel drive (MWD) options for outstanding tight-space maneuverability

RUSSELL FCTs are compliant with all relevant Australian, International, and country-specific standards. They are custom-manufactured at RME’s ISO-certified production facility in Australia, and supported by our regional Service Centres around the world.

RUSSELL CLASSIC FEED CHUTE TRANSPORTER

RUSSELL Classic FCTs will take the heavy load of the mill feed, and load off the plant floor, with ease and utmost safety.

Read more

RUSSELL MULTI-WHEEL FEED CHUTE TRANSPORTER

RUSSELL Multi-Wheel FCTs significantly reduce floor point loads with smart load distribution technology.

Read more

RUSSELL RAIL FEED CHUTE TRANSPORTERS

RUSSELL Rail FCTs are field proven to withstand heavy loads and harsh plant conditions.

Read more

FEED CHUTE BASES

RME’s Unpowered Feed Chute Bases (UFCBs) interface between embedded floor rails, feed chutes and RME’s Powered Feed Chute Transporters (classic or multi-wheeled)

Read more

RUSSELL HPGR TRANSPORTERS

Built for extreme loads, RUSSELL HPGR Transporters ensure precision handling of High Pressure Grinding Rolls.

Up to 110T capacities.