Trust RME to raise the standard

RME 24/7/SERVICE

RME 24/7/SERVICE ensures Customers have access to trusted OEM engineering know-how when they need it – whether onsite or collaborating online in real-time.

RME 24/7/SERVICE ensures Customers have access to trusted OEM engineering know-how where and when they need it. Whether helping onsite, or collaborating online in real-time, our customised, personalised asset support services will deliver optimised relining, mill availability and performance.

BENEFITS

- Right expertise, right time, right place 24/7.

- Faster time-to-resolution from OEM factory-trained technicians.

- Certified aftermarket parts assure warranty, safety and compliance.

- Reduced operational risk with safe machine working conditions.

- Enhanced local operator knowledge and skill through OEM collaboration.

- Optimised asset lifecycle productivity and cost.

- Improved maintenance shutdown predictability.

- Faster, more efficient, safer relines.

ADDITIONAL INFORMATION

-

- Access RME electromechnical, hydraulic, robotics expertise, factory-trained technicians 24/7

- Always-connected, tailored OEM collaboration – onsite, online, RME workshop

- Dedicated start-up and shutdown support, pre and post-operation inspections

- RME Mill Relining System diagnostics, intelligence and insight

- Technical support, scheduled servicing, part rotations, machine rebuilds

- Safety and automation technology upgrades

- OEM certified factory-approved spare parts provisioning

- Condition-based monitoring and preventative maintenance programs

- Machine operator training and skilled onsite crews

- MILL RELINE DIRECTOR and MILL RELINE DIRECTOR Safety programs

- Feedback for optimal configuration of grinding circuit service space / equipment layout to facilitate best-in-class reline events

-

Leverage RME’s unique OEM domain expertise for:

-

- Custom manufactured, commissioning and in-service support – enhance asset integrity and lifecycle management programs. Make time for proactive tasks which deliver sustainable improvements in mill relining and concentrator profitability.

- Operational and cost efficiencies – achieve relining shutdown predictability. Reduce CAPEX by optimising existing asset performance.

- Continuous monitoring and insight – use condition monitoring and predictive data to increase asset reliability, availability and safety.

- Future-proofed mill relining operations – ensure relining assets evolve to operate in safer, more efficient ways.

- Leverage emerging automation technologies for step-changes in productivity, safety and risk.

-

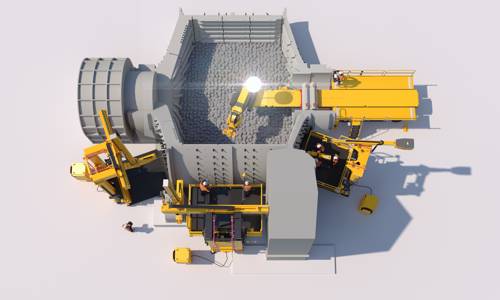

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs engineered, manufactured and delivered.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME equipment & services.

"Since inception our mission has remained: Help the minerals processing industry achieve new levels of reline speed and safety with the best available technology and individualised support. That’s why we’ve enhanced our broad-based services offerings with secure, digitally-connected collaboration capabilities. Customers now have dedicated access to OEM expertise 24/7 no matter where they are in the world."

Related products

OEM PARTS

Genuine quality parts are precision-manufactured, compliant, tested and certified for every piece of equipment – delivering superior reliability, longevity and safety.

Read more

ON-SITE EQUIPMENT COMMISSIONING

To ensure our Customers achieve the full potential from their RME Mill Relining System, RME delivers a range of after sales services.

Read more

ANNUAL SERVICING

Relining requires critical attention to safety. Risks increase when harsh conditions and usage impact asset integrity. Ensure annual inspections and servicing are a priority.

Read more

RUSSELL CLAW

Introducing the RUSSELL Claw – the new master of muck-out and eliminator of manual liner slinging.

Lifting capacity up to 8000 kg.

SS&O Sales Team

Matthew B. Thompson

Service Account Manager - APAC

Gary Medill

Service Account Manager - APAC

Denny Wisely

Vice President Sales & Business Development - North America

Samuel Mossaad

Service Account Manager - Canada

Lyle Hobbs

Service Account Manager - North America