21 March 2024

Austmine Mining Innovation Roadshow: 'The art of engineering innovation'

See Simon Thompson, RME's General Manager of Engineering, present "The Art of Engineering Innovation: Sharing Our Learnings and Why This Matters to RME" at the Austmine Mining Innovation Roadshow.

Read more

08 March 2024

From canvas to copper: An interview with RME’s Chief Customer Officer

For this year's International Women's Day (IWD), themed ‘Inspire Inclusion’, we had the honour of speaking with RME's Chief Customer Officer, Cherylyn Russell. Her generous insights offer a unique perspective on diversity and inclusion at RME and the broader mining sector.

Read more 21 March 2024

Austmine Mining Innovation Roadshow: 'The art of engineering innovation'

Video

Read more

08 March 2024

From canvas to copper: An interview with RME’s Chief Customer Officer

RME article

Read more

21 December 2023

RME's transformative year in review – 2023

Blog

Read more

30 November 2023

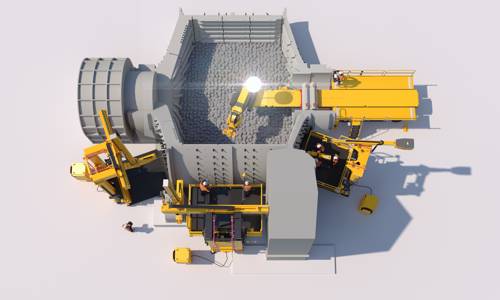

RME expands RUSSELL Liner Exchange Machine range

Media Release

Read more

30 October 2023

In conversation with industry leader, Dr John Russell

RME article

Read more

17 October 2023

RME deploys world’s first system for relining from outside the mill

Media Release

Read more

02 August 2023

RME Certified Training is your safety advantage

Blog

Read more

24 July 2023

RME appoints General Manager of Engineering, Simon Thompson

Media Release

Read more

23 June 2023

Women engineers help make safety seen – celebrating INWED 2023

RME article

Read more

06 June 2023

Using genuine spare parts to manage unpredictability

Blog

Read more

28 March 2023

RME'S digital transformation update for our Customers and suppliers

Company update

Read more

22 December 2022

RME receives Zijin Mining 2022 Annual Supplier Award

Blog

Read more